HENRI project started successfully

September 21, 2023 was marked in the modern history of NAFTA thanks to the HENRI project – The first Slovak IPCEI hydrogen project. On this day, in the beautiful surroundings of the Jurkovič heating plant, we organized the initial conference of the project. The location of the conference was chosen symbolically, as it is a historical funcionalist space in the modern center of Bratislava, which brings its innovativeness closer to connecting the gas infrastructure with hydrogen.

The conference was opened by the CEO of NAFTA, Martin Bartošovič, who highlited the importance of the project considering the future direction of the company. He also appreciate the partners who, despite the long time that passed from the submission of the project application to the start of its implementation, withstand and met together in Bratislava to formally launch the project.

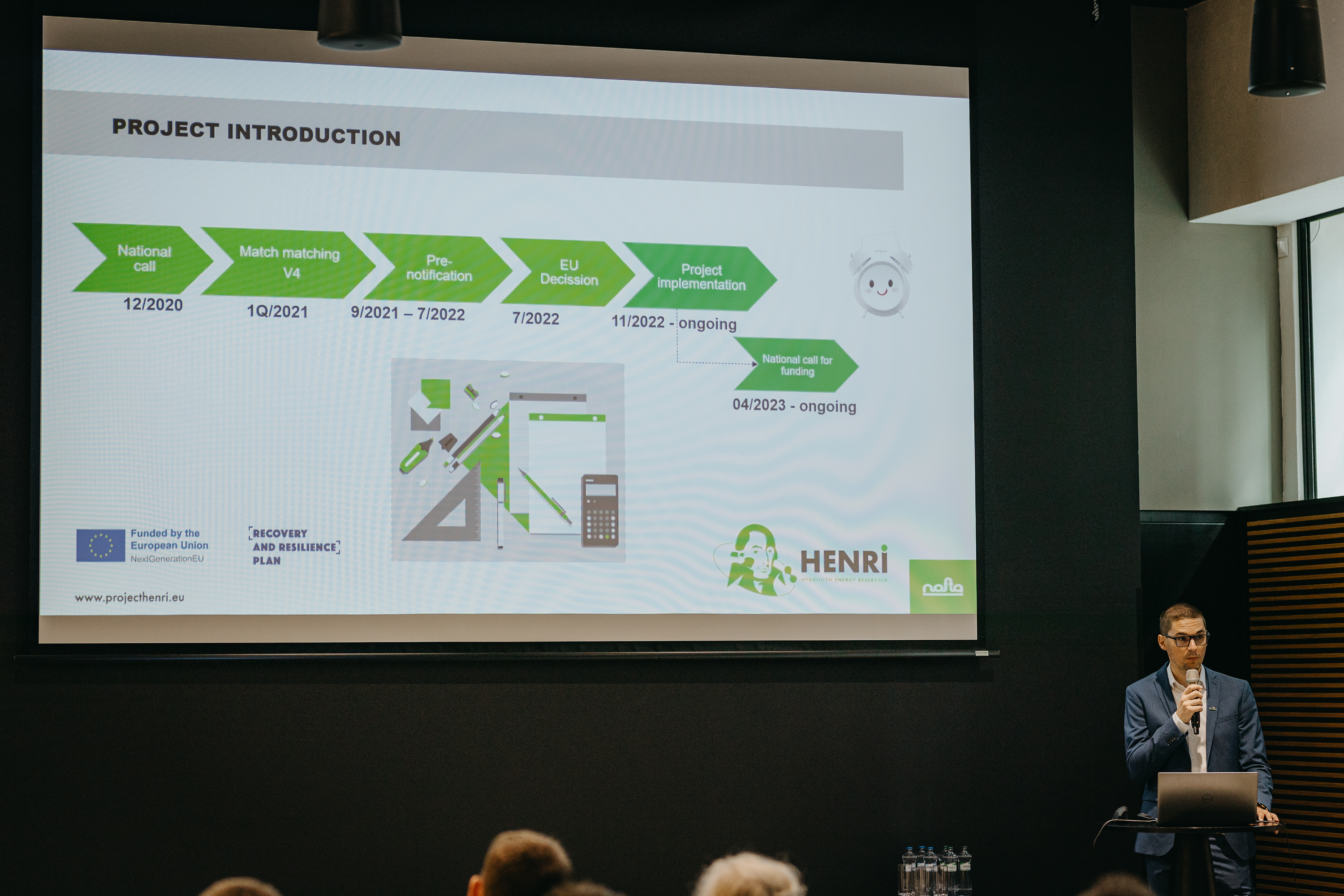

Subsequently, the project manager Roman Zavada presented the project as a whole. He showed where the project is today from both sides, from the point of view of formal requirements (obtaining a grant, etc.) and from the point of view of the tasks set out.

Although the project has already been presented several times in the Slovgas magazine, let’s remind a few basic facts.

The HENRI Project aims to:

- Identify suitable structures for hydrogen storage in Slovakia

- Define the maximum permissible concentration of hydrogen that could be stored in selected structures

- Process a bearing model and

- Physically test the selected structure with a pilot test.

But back to the conference, where in the framework of two expert panels, the involved partners presented their tasks in the project, what they are going to do, with what equipment, under what conditions, etc. The professional part of the conference was opened by Dr. Júlia Kotúlová from the Slovak Academy of Sciences, who presented the method of creating a methodology for assessing of geological structures together with the specification of the data that will be needed for the creation of this methodology.

In the next lecture, Rico Rockmann from the DBI company presented a range of tests that, as part of the HENRI project, will be implemented on the bearing rock with the aim of identifying geochemical reactions that could occur, as well as their effect on the properties of the rock, e.g. permeability etc. The experiments will be implemented at real bearing pressures, temperatures, as well as different salinity depending on the structure, while the rock samples will be long-term exposed to hydrogen at different concentrations for a period of twelve months. In total, three different objects will be tested in the range from 80 to 200 bar, with temperature from 40°C to 90°C, with a salinity from 16 000 to 24 000 mg/l. In addition to the tests of the effect of hydrogen on the bearing rock, the effect of hydrogen on the cement sample will be also tested, while the effect of hydrogen on the cement core will be observed microscopially. Permeability, X-ray spectroscopy, etc. will also be measured.

In another post, Dr. Eberhard Jahns from Gesteinslabor company presented tests, which will be implemented in the project, with the aim of identifying the effect of hydrogen on the sealing layer, determining the displacement pressure and measure the diffusion coefficients. As part of the tests, it will be nessesary to prepare samples of the sealing layer and perform a CT scan to document the integrity of individual samples. Subsequently, individual samples will be saturated with hydrogen in a simulated test, while the output will be the calculation of diffusion coefficients. Measuring the displacement pressure allow to define the maximum acceptable pressure at which gas can be stored in the selected structure.

Dr. Martin Wagner from MicroPro presented tests that aim to define and quantify the microbial reactions that can potentially occur when hydrogen is injected into a selected structure. These tests will be implemented in pressure vessels with original bearing water samples and core samples, exposed to hydrogen in different concentrations with natural gas. Changes in pH, temperature, changes in gas and liquid phase composition, changes in microbial composition before and after the experiment, and more will be measured.

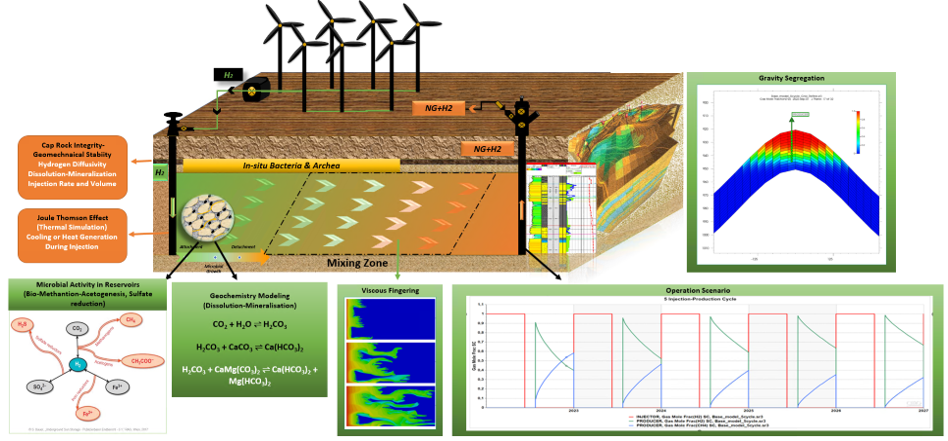

After short break, the conference continued with the second expert panel, which was started by Nazik Moeinin from DBI. This presentation was aimed at introducing the bearing modeling task. In this activity, several models will be processed, while already existing data, as well as data obtained from realized laboratory experiments, will be used as inputs. The goal is to process a model simulating the behavior of hydrogen in the bearing, defining the most suitable probe for injection and the performance parameters of injection or mining.

The conference continued with two presentations focused on testing materials, specifically steel. In the first of them, Dr. Matthias Eichinger from TU Leoben presented the first part of the experiments aimed at testing the effect of hydrogen on steel under different conditions, i.e. different pressures, temperatures, wet gas, possible presence of methanol, etc.

This presentation was followed by Christophe Mendibide from French Corrosion Institute, where the second part of the experiments should be tested to assess the effect of hydrogen on selected steel types.

Despite the fact that, for various reasons, not all partners took part in the conference, e.g. from TU Košice and TU Clausthal, the conference had a high professional quality, which was confirmed by invited guests from various sectors, from experts to gas storage operators from various countries – Slovakia, the Czech Republic, Poland, Hungary, Austria, France, Germany, Italy, and all are already looking forward to the next conference, where the first results of laboratory experiments will be presented.

Finally, thanks to the entire team of people who prepared the event at a very high level.

Prepared Ing. Roman Zavada